The term hydraulics is derived from the Greek language and is composed of the terms “hydro” (water) and “aulos” (power) (pipe). When translated, this refers to the usage of water that is put in motion by a pipe or a series of pipes.

In hydraulic systems, hydraulic fluid is pressured to increase its flow rate. When you take away space from a liquid, you produce pressure in that liquid. This is most effective when liquids are contained inside a closed chamber or within a pipe system.

Consider the following scenario: we have water in a water squirt cannon. The more we squeeze the water pistol together, the greater the amount of pressure that is generated. This continues until the liquid is pushed and displaced to such a degree that it ultimately squirts out of the aperture when the pressure is applied in hydraulikanlage.

When pressure is applied, energy is generated.

Pressure is formed when the liquid attempts to expand uniformly, and the more space you take away from it, the more pressure is created. Hydraulic systems take advantage of this pressure by transforming it into energy, which is then used by the system. Heavyweights and massive machinery may be moved with the aid of this flowing energy, which makes it feasible to raise them hydraulikanlage.

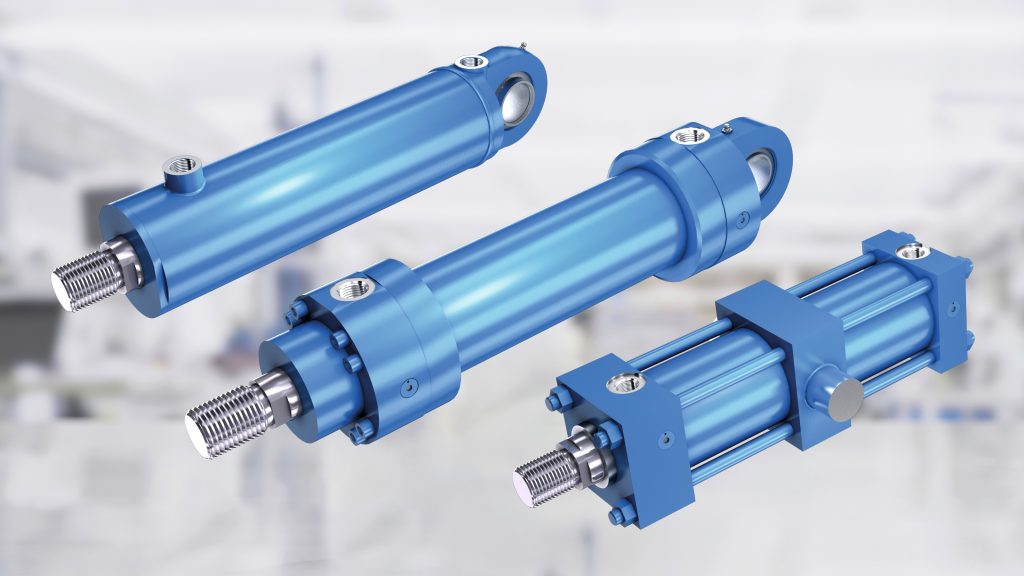

The following is the fundamental principle of the hydraulic drive: A pump, which is operated by a motor, applies pressure to a liquid, resulting in the creation of a volume, also known as the flow rate. This, together with the pressure energy it has collected, is transferred to the hydraulic motor or hydraulic cylinder, where it is turned into mechanical energy. Following this introduction, we’ll take a deeper look at the different components of this system with hydraulikanlage.

Furthermore, water is seldom utilised as a conveying liquid in hydraulic systems nowadays since water, owing to its varying states of aggregation depending on the temperature, has features that are disruptive for this technology, such as contracting or evaporating when it is heated, among other things. Special oil is now often utilised as a hydraulic fluid in hydraulic systems to achieve the highest potential efficiency.

What is the function of a hydraulic pump, and how is the pressure generated inside it?

It is now evident how hydraulic fluid is compressed on a fundamental level of understanding. However, how does the pressure in a hydraulic pump get created?

Take, for example, the brakes on a vehicle, which, indeed, are largely hydraulic in their operation. When you apply pressure to the brake pedal in your automobile, a piston in the brake cylinder, which holds the brake fluid, is propelled forward. This piston compresses the volume of the cylinder, causing the fluid to become pressured.

The pressure that builds up here is transferred to the rear brakes, which apply pressure to the tyres and cause them to slow down. Every pump has a failure at some time. This is especially true since hydraulic pumps are very sensitive and have an impact on the whole hydraulic system. Problems might emerge mostly as a result of long-term usage or a failure to take adequate safeguards.

The bundling of energy is also employed in other fields of business, such as laser cutting, where it is very effective. In a hydraulikanlage., the hydraulic pump is responsible for delivering the hydraulic fluid. It removes hydraulic oil from a tank and pumps it into the hydraulic system with the help of a pump. The pump can create a specified volume and pressure depending on the needs. For a hydraulic pump, the most essential factors are, on the one hand, its pressure range (measured in the bar), and, on the other hand, its flow rate (measured in litres per minute).